Tel: +86 755 23001358 +852 60666694

E-mail:kefu@honorsing.com

SZ Add: H2206 Liuhe Building, No.168 Shenshan Road, Pingshan District, Shenzhen.

HK Add: Rooms 1318-19, 13/F, Hollywood Plaza, 610 Nathan Road, Mongkok, Hong Kong.

TG-200 series Thermal Grease(UL certification)

• UL certification

• High thermal conductivity and low thermal impedence

• Good screenability

• Room temperature storage

• No post "cure" required

• Ultra-low settling, room temperature storage

• Exceptional value

THERMALLY CONDUCTIVE GREASE PROPERTIES OVERVIEW

| TG 200 Series | Thermal

Conductivity (W/m⋅K) |

Viscosity (cps) |

Density (g/cm3) |

WeightLoss (% @200°C×8hrs) |

Volatility (% @200°C×8hrs) |

| TG-213 | 1.3 |

103,000 |

2.53 |

<0.01 |

<0.1 |

| TG-215 | 1.5 |

103,000 |

2.53 |

<0.01 |

<0.1 |

| TG-225 | 2.5 |

125,000 |

2.75 |

<0.01 |

<0.1 |

| TG-235 | 3.5 |

135,000 |

2.85 |

<0.01 |

<0.1 |

| TG-240 | 4.0 |

150,000 |

2.95 |

<0.01 |

<0.1 |

| TG-250 | 5.0 |

160,000 |

3.05 |

<0.01 |

<0.1 |

THERMALLY CONDUCTIVE GREASES HELP TO PREVENT "PUMP OUT" AND DEGRATION ISSUES

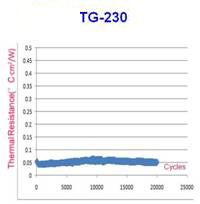

Generally, greases have problems with “pump-out” and degradation. It will affect the heat conductive in an important application where reliability is key. Chooyuchem's greases are formulated with unique silicone fluids that interact with filler particles and actually help bind the filler to the matrix. This prevents the separation and “pump-out” often associated with greases. As for degradation, you can see from power cycling data(see the left figure of TTV testing) that even after 20,000 power cycles the performance is stable.

Screen Printing of Grease

![]()

|

|

|

|

between CPU |

Between LED boards |

In electronic water-heater |

In solar panel |

Application Notes

TG-200 Series UL certification

Theramlly conductive grease replacing guide

Heat conductive issue for high power COB LED