Phase change material

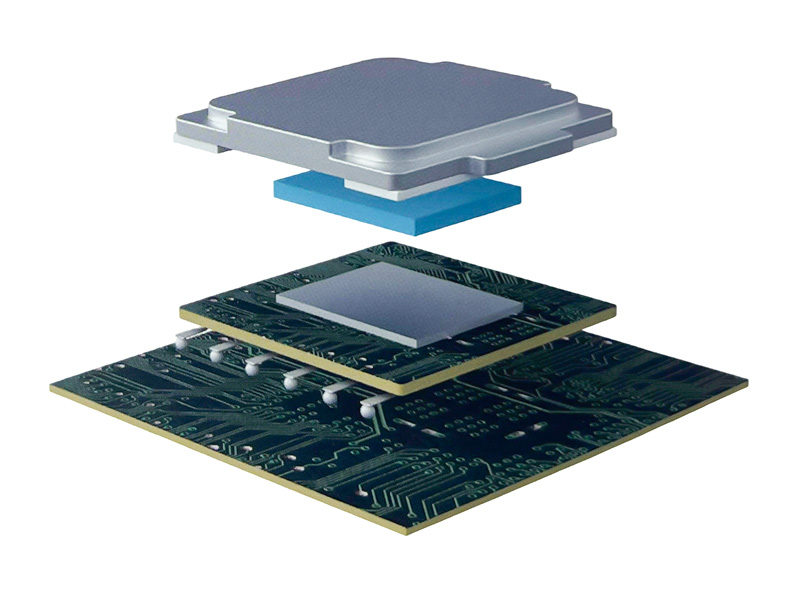

Phase change materials (PCMs) are commonly used as matrix materials for thermal interface applications. Due to their solid state at room temperature and softening upon heating, they can completely fill the gaps between contact surfaces, achieving thin layers and high reliability without pumping problems.

storage time12 months (storage conditions refer to product packaging)Packing SpecificationSheet, roll and die cut parts

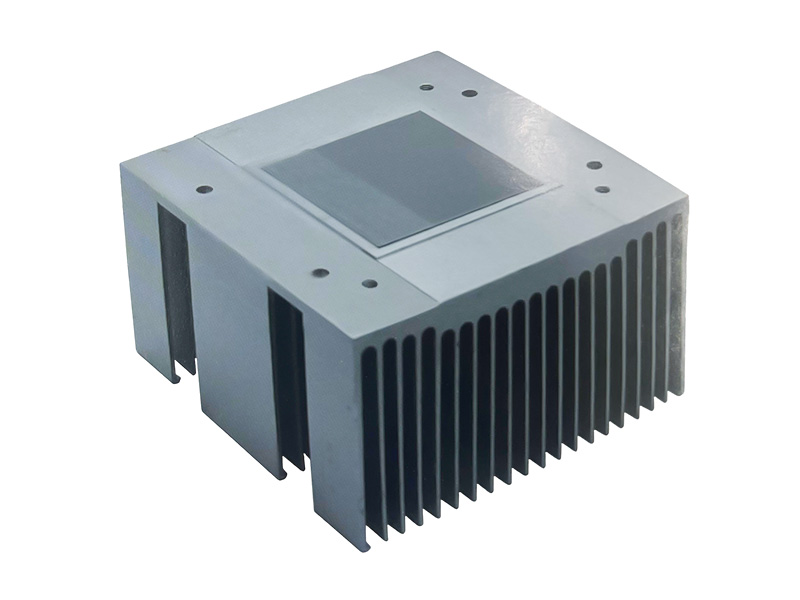

Typical Applications

·Power control unit, inverter, vehicle electronic equipment

·IGBT

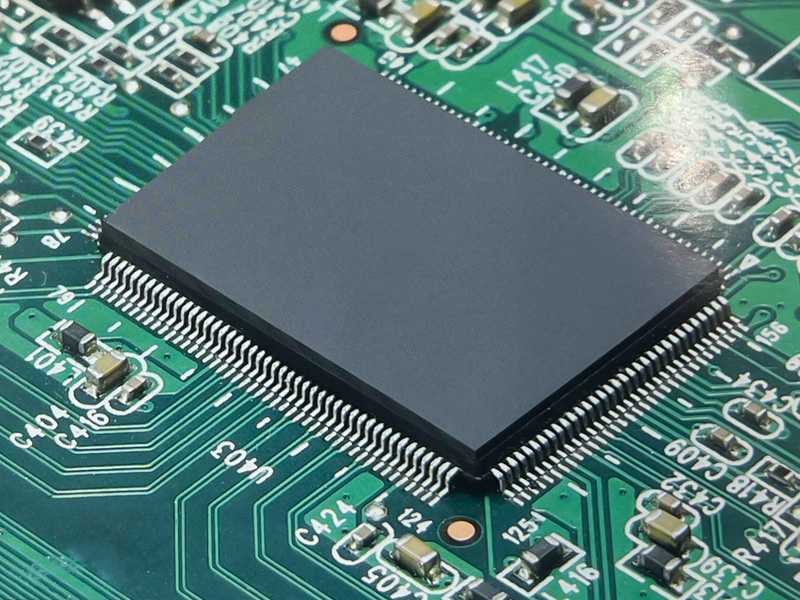

·Server, Supercomputing, Video Graphics Array (VGA) card, AI, GPU/CPU/Desktop, Solid State Drive

·Switches, routers, base stations

·Tablets, gaming consoles, laptops, smartphones, sports cameras

Typical performance

| Phase change material | DM-200 | DM-360 | DM-400 | DM-500A | DM-700 | Test Standard |

| color | gray | gray | gray | gray | gray | visual estimation |

| thickness mm | 0.127-0.25 | 0.13-1.0 | 0.2-1.0 | 0.2-1.0 | 0.2-1.0 | - |

| Phase transition temperature ℃ | 50 | 50 | 45 | 45 | 45 | DSC |

| Specific gravity g/cm3 | 2.1 | 2.85 | 2.56 | 2.6 | 2.5 | Helium true density method |

| Thermal conductivity W/m-K | 2.0 | 3.5 | 4.0 | 5.0 | 7.0 | Hot Disk |

| Thermal resistance C · in ²/W (80 ° C, 40psi) | 0.04 | 0.037 | 0.013 | 0.011 | 0.009 | ASTM D5470 |

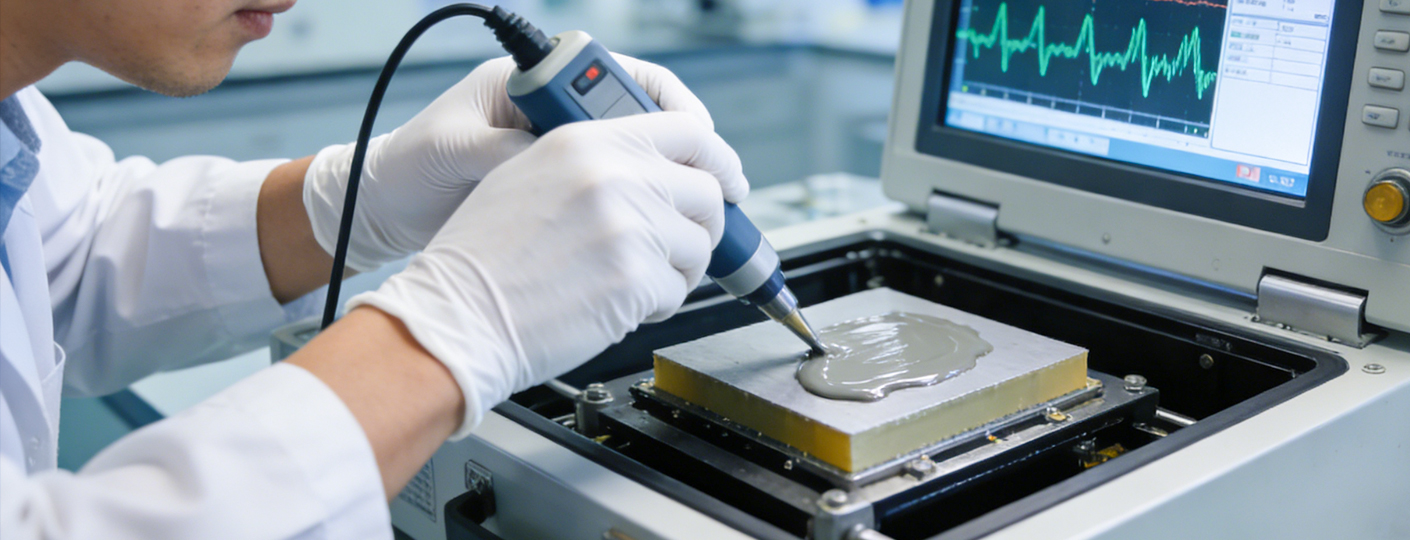

TIM1/TIM1.5 material

With the advancement of chip technology, smaller chips and higher power make thermal solutions a key part of IC packaging design.

This highly thermally conductive material is designed to meet current and future thermal management requirements and can be used for the entire temperature sensitive component.

storage time6 months (storage conditions refer to product packaging)Packing SpecificationNeedle cylinder installation -30cc/100cc/150cc/300cc; It can also be provided on demand.

Typical Applications

·IC

·Laptop computer

·Video graphics board

Typical performance

| TIM1/1.5 material | DPG-400 | DPG-800 | DHG-400 | DHG-800 | Test Standard |

| color | gray | gray | gray | gray | visual estimation |

| Viscosity CPS | 400,000 | 600,000 | 500,000 | 750,000 | Huck rheometer |

| Flow rate g/min | 150 | 120 | 90 | 70 | ASTM D2240 |

| Hardness Shore oo | 40 | 45 | 15 | 14 | ASTM D2240 |

| Specific gravity g/cc | 2.5 | 2.5 | 2.6 | 2.5 | ASTM D792 |

| Thermal conductivity W/m · K | 4.0 | 8.0 | 4.0 | 8.0 | ASTM D5470 |

| Thermal resistance ℃ · in ²/W (80 ° C, 40psi) | 0.01 | 0.009 | 0.009 | 0.01 | ASTM D5470 |

| Curing time 125 ° Cmin | 60 | 60 | 30 | 30 | - |

carbon fiber material

Carbon fiber material products have ultra-high thermal conductivity while maintaining good elasticity, providing more choices for some special demand scenarios.

storage time12 months (storage conditions refer to product packaging)Packing SpecificationSheet and die cut parts

Typical Applications

·Electronic components

·Network communication equipment

·Aerospace equipment

·Energy

Typical performance

| carbon fiber material | DP-FC150 | DP-FC250 | DP-FC300 | DP-FC500 | Test Standard |

| color | black-gray | black-gray | black-gray | black-gray | visual estimation |

| thickness mm | 0.5-5.0 | 0.5-5.0 | 0.5-5.0 | 0.5-5.0 | - |

| Hardness Shore oo | 45 | 45 | 50 | 60 | ASTM D2240 |

| Specific gravity g/cm3 | 1.6 | 1.8 | 1.9 | 2.2 | ASTM D792 |

| Thermal conductivity W/m-K | 15 | 25 | 30 | 50 | ASTM D5470 |

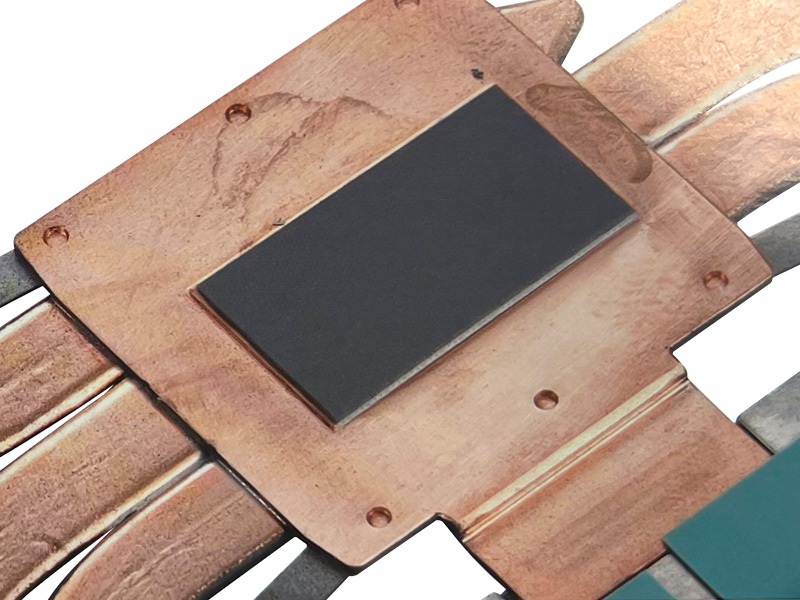

Thermal absorption wave plate

Thermal absorbing wave plate products can effectively reduce the interference of clutter on their own equipment, while exporting thermal energy. It is a material that combines both thermal conductivity and absorption functions.

storage time12 months (storage conditions refer to product packaging)Packing SpecificationSheet and die cut parts

Typical Applications

·Consumer electronics products

·Network communication equipment

·Chips, routers, navigation devices, digital cameras

·Military products

Typical performance

| Thermal absorption wave plate | DCA-F20 | DCA-F30 | DCA-F40 | Test Standard |

| color | gray | gray | gray | visual estimation |

| thickness mm | 0.5-3.0 | 0.5-3.0 | 0.5-3.0 | - |

| Hardness Shore oo | 45 | 45 | 45 | ASTM D2240 |

| Specific gravity g/cm3 | 4.2 | 4.3 | 3.5 | Helium true density method |

| Thermal conductivity W/m · K | 2.0 | 3.0 | 4.2 | ASTM D5470 |

| Thermal resistance ℃ · in ²/W (@ 30psi, 80 ° C) | 1.1 | 0.55 | 0.37 | ASTM D5470 |

| frequency of use | 1-18GHz | 1-18GHz | 1-18GHz | 1mm |

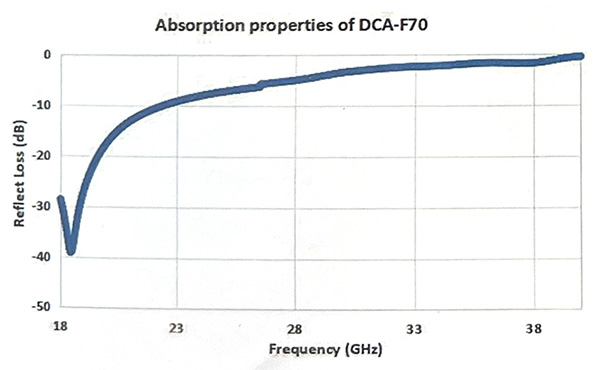

DCA-F70

A product with broadband absorption, good absorption effect, and extremely high thermal conductivity. It can convert electromagnetic wave energy into thermal energy for rapid loss, without causing electromagnetic waves to reflect back and forth in the shielding cavity.

DCA-F70 Typical Performance

| Thermal absorption wave plate | DCA-F70 | Test Standard |

| color | gray | Daily measurement |

| thickness mm | 0.5-3.0 | - |

| Hardness Shore oo | 45 | ASTM D2240 |

| Specific gravity g/cm3 | 2.2 | Helium true density method |

| Thermal conductivity W/m.K | 7.0 | ASTM D5470 |

| Thermal resistance ℃ · in ²/W (@ 30psi, 80 ° C) | 0.2 | ASTM D5470 |

| frequency of use | 20-40GHz | 1mm |

Conductive adhesive

Conductive adhesive products are filled with unique conductive particles, which have excellent aging reliability and can be used for substrates treated with metal, electroplating, or chromate.

storage time6 months (storage conditions refer to product packaging)Packing SpecificationNeedle tube packaging -300ml; canned -1kg; can also be provided on demand

Typical Applications

·Automotive Domain Controller

·Medical equipment

·Network communication equipment

·Aerospace equipment

Typical performance

| conductive adhesive | DS-AA45H | DS-AN45H | DS-NCSY01 | DS-NC60H | EM-221T | EM-212SF | Test Standard |

| Conductive filler | Ag/Cu | Ag/Ni | Ni/C | Ni/C | Ni/C | Ag/Cu | - |

| Viscosity Pa.s (0.5rpm; 150s; 25 ℃) | 700 | 500 | A:600 B:600 |

A:550 B:550 |

650 | - | Huck rheometer |

| Hardness Shore A after curing | 50 | 50 | 60-70 | 65 | 65 | 35 | ASTM D2240 |

| Specific gravity after curing g/cc | 3.0 | 3.8 | 2.3 | 2.2 | 1.9 | 2.4 | ASTM D792 |

| Shielding performance dB | >110 | >110 | >100 | >100 | >110 | >110 | |

| curing time | 30min/150°C | 24 hours/25°C | MIL-DTL-83528C (30MHz-10GHz) |

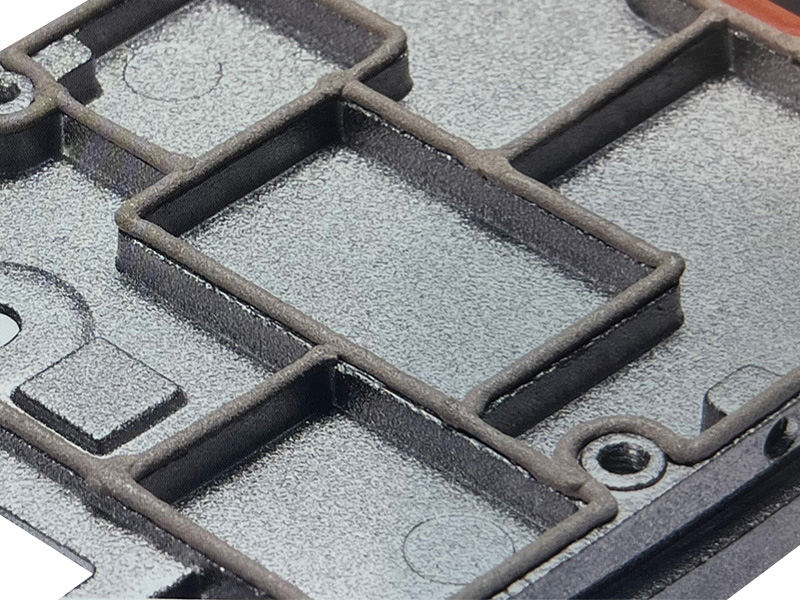

wave-absorbing material

Absorbing material products have excellent aging reliability, low volatility, and low oil permeability, which can meet the strict requirements for volatile condensates in scenarios. It can effectively reduce or eliminate surface current, cavity resonance, and frequency coupling.

storage time12 months (storage conditions refer to product packaging)Packing SpecificationSheet, die cut parts and syringe assembly

Typical Applications

·Consumer electronics products

·Aerospace equipment

·Network communication equipment

·Military equipment

Typical performance

| wave-absorbing material | DAM-1 | DAM-2 | DAM-3L | DAM-4L | Test Standard |

| color | gray | gray | gray | gray | visual estimation |

| Tensile strength Mpa | 3 | 3.6 | 3 | 3 | GB/T 528 |

| Tear strength KN/m | 23 | 22 | 25 | 24 | GB/T 228 |

| Fracture elongation% | 280 | 180 | 93 | 110 | GB/T 528 |

| volatility | 0.03% | 0.02% | 0.02% | 0.02% | 150°C/24h |

| Hardness Shore A | 70 | 75 | 75 | 80 | GB 2411-80 |

| Specific gravity g/cm3 | 4.2 | 4.4 | 4.5 | 4.5 | Helium true density method |

| frequency of use | 2-40GHz | 2-40GHz | 2-18GHz | <1GHz | SJ 20512-1995 |

| EMI attenuation @ 10GHz dB/cm | 32 | 54 | 87 | 110 | SJ 20512-1995 |

DAM-CS

A high absorption and flexible EMI material, constructed using adhesive method, with excellent process operability, high flow rate, and large thixotropy, suitable for small gaps, compact and difficult to operate applications.

| wave-absorbing material | DAM-CS | Test Standard |

| color | dark gray | visual estimation |

| Flow rate g/min (90psi, 60s) | 5 | - |

| Hardness Shore A | 45 | GB 2411-80 |

| Specific gravity g/cm3 | 4.2 | Helium true density method |

| frequency of use | >1GHz | SJ 20512-1995 |

| EMI attenuation @ 10GHz dB/cm | 63.8 | SJ 20512-1995 |

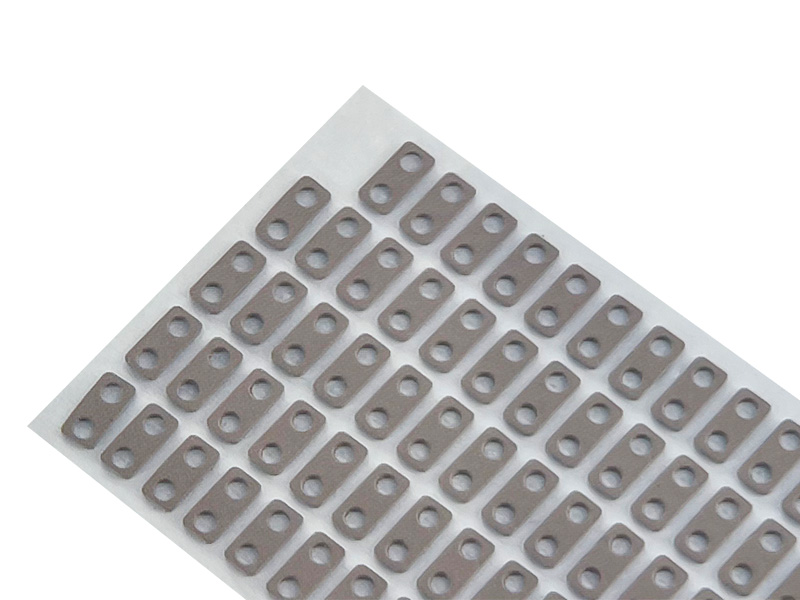

conductive rubber

Conductive rubber products not only provide high conductivity, but also have broadband shielding and environmental sealing effects, making them an economical and reliable electromagnetic shielding material.

storage time12 months (storage conditions refer to product packaging)Packing SpecificationPlate type, molded type, extruded type, die cut type

Typical Applications

·Small and medium-sized military electronic chassis, microwave waveguide system

·Aerospace, ships, military shelters, military electronic equipment

·Electronic products, telecommunications, high-frequency control equipment

·Electronic equipment with harsh environments such as electricity and railways

Typical performance

| conductive rubber | EM-011 | EM-021 | EM-041 | EM-051 | Test Standard | |

| Conductive filler | Ni/C | Ag/AI | Ag/Glass | Ag | - | |

| Hardness Shore A | 60±7 | 65±7 | 65±7 | 60±7 | ASTM D2240 | |

| Specific gravity g/cc | 1.9±0.25 | 2.3±0.25 | 1.9±0.25 | 1.7±0.25 | ASTM D792 | |

| Shielding performance dB | 30MHz (E-field) | 60 | 90 | 70 | 90 | MIL-DTL-83528C MIL-STTD-285 |

| 100MHz (E-field) | 100 | 115 | 100 | 120 | ||

| 500MHz (E-field) | 100 | 110 | 100 | 120 | ||

| 2GHz (planar field) | 100 | 105 | 100 | 120 | ||

| 10GHz (planar field) | 100 | 100 | 100 | 120 | ||

EM-031

A silicone rubber filled with copper silver plated conductive particles, whose excellent conductivity is widely used in electromagnetic sealing applications, providing excellent water vapor sealing for the interfaces and seams of the chassis.

| conductive rubber | EM-031 | Test Standard | |

| Conductive filler | Ag/Cu | - | |

| Hardness Shore A | 65±7 | ASTM D2240 | |

| Specific gravity g/cc | 3.4±0.25 | ASTMD792 | |

| Shielding performance dB | 30MHz (E-field) | 90 | MIL-DTL-83528C MIL-STTD-285 |

| 100MHz (E-field) | 120 | ||

| 500MHz (E-field) | 120 | ||

| 2GHz (planar field) | 120 | ||

| 10GHz (planar field) | 120 | ||