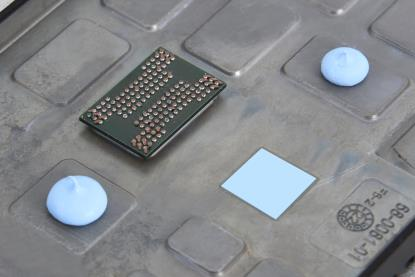

High thermal conductivity, low thermal resistance, low stress;

Viscous, with good thixotropy, does not flow, and has good wetting properties on the contact surface;

Can be extruded and used for automatic dispensing;

No need for curing, no deformation when no pressure is applied, good vibration resistance, easy to rework;

Superior resistance to high and low temperatures, weather, aging, and electrical insulation;

Passed UL94V-O flame retardant certification and RoHS hazardous standard verification.

No need for curing, fill the gaps between the heating and cooling surfaces that are uneven and irregularly sized. If the gaps are large, they need to be fixed with a device

Two component thermal conductive gel has long-term reliability and excellent flexibility. The enhanced adhesion between the polymer matrix and filler greatly reduces the problem of oil separation during storage.

A two-component thermal interface material that solidifies at room temperature or high temperature, with ultra-high thermal performance and excellent flexibility, as well as low volatility, designed specifically for connecting fragile components with high morphology or stacking tolerances to ordinary heat sinks and shells.

| Product Name | Thermal conductivity (W/m · K) | Viscosity (cP) | Density (g/cm ²) |

| HTG-510-GEL | 1.0 | 1.75 million to 750000 | 2.60 ± 0.20 |

| HTG-520-GEL | 2.0 | 2 million to 1 million | 2.80 ± 0.20 |

| HTG-530-GEL | 3.0 | 2.5 million to 1 million | 3.10 ± 0.20 |

| HTG-540-GEL | 4.0 | 2.5 million to 1 million | 3.30±0.20 |

| HTG-550-GEL | 5.0 | 4 million to 1.5 million | 3.40±0.30 |

| HTG-560-GEL | 6.0 | 4.5 million to 1.5 million | 3.45±0.30 |