Adhesive layer<0.1mm after bonding, high thermal conductivity, low thermal resistance, low modulus;

Low settlement, low oil permeability;

Not solidified, easy to rework;

Superior resistance to high and low temperatures, weather, aging, and electrical insulation;

Passed UL94V-0 flame retardant certification and RoHS hazardous standard verification;

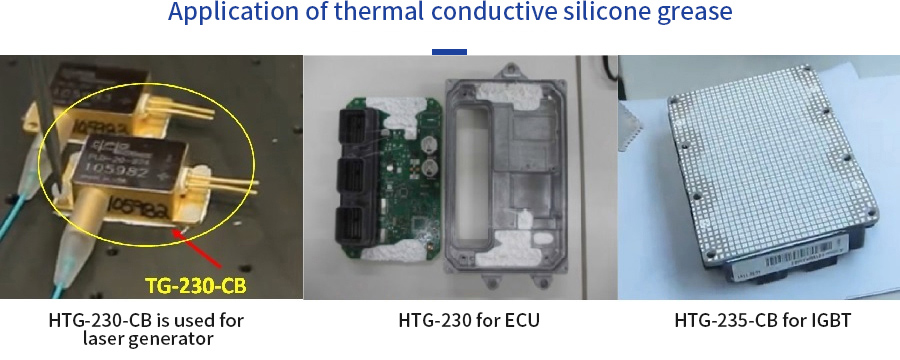

Thermal conductive silicone grease filler has a small particle size, which can ensure a minimum thickness of<0.1mm. It is widely used in high-power laser generation modules, laser drive power modules, and IGBT thermal conductivity

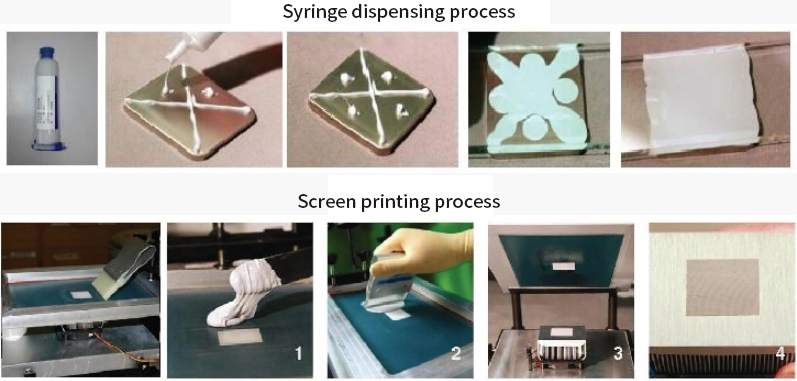

No need for curing, used for filling gaps between smooth and flat heating and cooling surfaces. The filling gap is extremely thin and requires device fixation.

The material of the screen is generally nylon, and the thickness of the coating is related to the mesh size of the screen. The smaller the mesh size, the larger the diameter of the screen. Under the same printing conditions, the thickness of the coating is also thicker. The coating thickness corresponding to different mesh sizes is shown in the table below

| Mesh size of wire mesh | Wire mesh thickness (mm) | Expected thickness of silicone grease (mm) |

| 60 | 0.21 | 0.135~0.145 |

| 80 | 0.20 | 0.12~0.15 |

| 110 | 0.15 | 0.09~0.10 |

Typical performance

| Product Name | Thermal conductivity (W/m · K) | Viscosity (cP) | Density (g/cm ³) |

|---|---|---|---|

| HTG-210 | 1.0 | 110000 ± 30000 | 2.10±0.20 |

| HTG-210-CB | 1.0 | 90000 ± 30000 | 2.53±0.10 |

| HTG-215 | 1.5 | 110000 ± 30000 | 2.60±0.10 |

| HTG-215-CB | 1.5 | 195000 ± 55000 | 2.80±0.10 |

| HTG-220 | 2.0 | 120000 ± 30000 | 2.85±0.15 |

| HTG-220-CB | 2.0 | 180000 ± 50000 | 3.00±0.10 |

| HTG-225 | 2.5 | 120000 ± 40000 | 2.925±0.075 |

| HTG-225-CB | 2.5 | 120000 ± 40000 | 3.20±0.20 |

| HTG-230 | 3.0 | 160000 ± 60000 | 3.30±0.30 |

| HTG-230-CB | 3.0 | 220000 ± 70000 | 3.20±0.30 |

| HTG-235-CB | 3.5 | 250000 ± 80000 | 3.30±0.30 |

| HTG-240-CB | 4.0 | 260 thousand | 3.35±0.30 |