DP-F2500 is a soft self-adhesive thermal pad filled with ceramic particles, with a light gray appearance and a thickness of 0.5-8mm to choose from. It has a thermal conductivity of 2.4W/m · K, a working temperature of -50-200 ℃, UL94 V0 level fire resistance, high elasticity and high tensile strength, and is suitable for rough surfaces, providing stable heat dissipation for medium power equipment

Core strengths

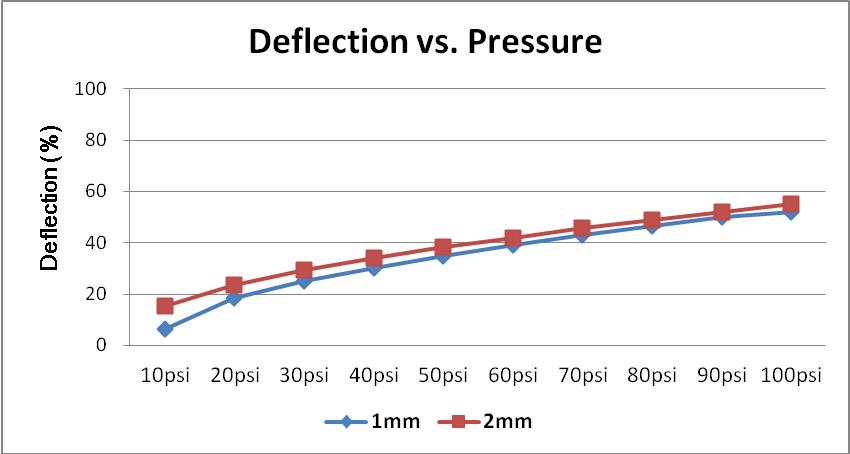

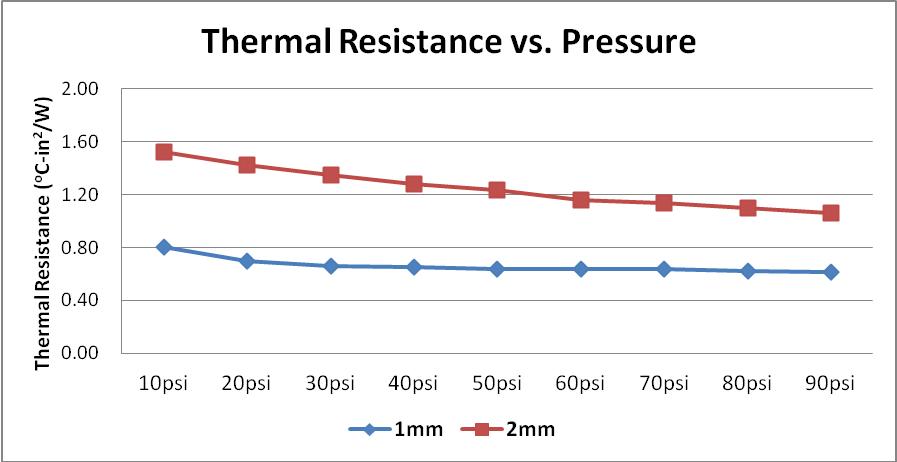

【 Soft and high elasticity, strong filling ability 】 45 Shore 00 has soft characteristics, with a thickness of 3mm and a deformation of 40% under 60psi pressure. It can fully fill various rough surface gaps, eliminate air gaps, and achieve tight fitting under low pressure

【 Self adhesive and easy to use, efficient installation 】 It comes with adhesive without the need for additional coating, and can be applied immediately after tearing off the film to avoid residual adhesive contamination of the device. It is compatible with automated production and manual installation, greatly simplifying the assembly process

【 Excellent mechanical performance and high stability 】 With a tensile strength of 35psi and an elongation at break of 85%, it has both flexibility and structural stability. Long term use poses no risk of cracking or detachment, making it suitable for complex installation scenarios

【 Safe and weather resistant, with wide adaptability 】 The working temperature covers -50-200 ℃ and can withstand extreme high and low temperatures; UL94 V0 level fire certification, dielectric breakdown strength>250VAC/mil, excellent insulation performance, widely used in multiple industries

Applicable scenarios

Core application devices/components

Industrial electronics: small power module, frequency converter auxiliary heat dissipation, high elasticity filling rough surface, high tensile strength suitable for vibration environment

Communication equipment: router, set-top box internal heat dissipation, self-adhesive design simplifies assembly, soft bonding does not damage precision components

Consumer electronics: projectors, audio equipment, 2.4W thermal conductivity efficiency to meet medium power heat dissipation, light gray appearance suitable for product interior

LED lighting: LED street lights, stage light substrates, fire certification meets safety standards, gap filling improves heat dissipation uniformity

Instructions for Use

1. Clean the surface and heat dissipation structure of the heating element with anhydrous ethanol, remove oil and dust, and air dry until there are no residues;

2. Confirm that the product thickness matches the installation gap, cut it to the required size as needed, and remove the protective film on the surface of the thermal pad;

3. Align the installation position with the thermal pad and lightly press it to ensure full contact between the thermal pad and the surface, ensuring no residual bubbles;

4. In conjunction with screw locking or buckle fixation, it is recommended to apply a pressure of 20-60psi to ensure a stable fit without the need for additional adhesive coating.

Precautions

Storage conditions: Sealed and stored in a cool and dry place (8-28 ℃), avoiding direct sunlight and high temperature and humidity environment. Shelf life is 12 months from the date of production

Usage taboos: Avoid contact with strong acids, bases, and organic solvents, and prohibit use in food contact scenarios and extreme vacuum environments

Thickness selection: Choose the appropriate thickness based on the installation gap, and it is recommended to reserve 10-20% compression to ensure the fitting effect

Customization Description: Supports cutting customization within the thickness range of 0.5-8.0mm, specific length and width dimensions and required thickness need to be provided

| technical indicators | specific numerical value | Test Standard |

| thermal conductivity | 2.4 W/m·K | Hot Disk |

| color | pale gray | visual inspection |

| Shore hardness | 45 Shore 00 | ASTM D2240 |

| tensile strength | 35 psi | ASTM D412 |

| Deformation @ 3mm, 60psi | 40% | ASTM D575 |

| Performance testing curve |  |

|