High thermal conductivity, low thermal resistance;

Addition reaction, no volume change occurs during the curing process;

Has high thixotropy and can be uniformly filled into gaps of different thicknesses under low pressure;

Fast curing at room temperature or high temperature, 100% solid, no exudate after curing;

Superior resistance to high and low temperatures, weather, aging, and electrical insulation;

Superior chemical and mechanical stability;

Passed UL94V-0 flame retardant certification and RoHS hazardous standard verification.

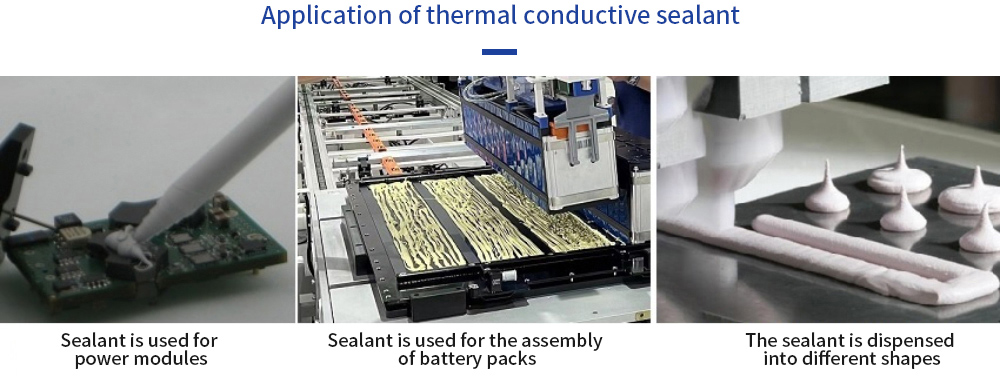

Two component thermal conductive silicone, cross-linked into a solid elastomer at room temperature, also known as gap filler, can be used as a heat source on PCB boards to fill irregular gaps between the surrounding chassis or heat sink. The adhesive enhancement formula of two-component thermal conductive silicone can provide both thermal conductivity and bonding functions for multiple materials simultaneously. At present, the thermal conductivity of the two-component thermal conductive silicone we provide ranges from 1.5 to 5.0 W/m · K. Easy to extrude and operate. After curing, it shows low hardness and low bonding strength. It can be used as a two-component room temperature curing thermal conductive gel, or as a two-component super soft pad that can be dispensed. The cured gel is not sticky, and is easy to remove and replace. 100% curing at room temperature without gas release during curing, can be accelerated by heating to improve production efficiency.

Performance indicators of two-component thermal conductive silicone sealant (room temperature curing)

| Product Name | mixing ratio | Thermal conductivity (W/m · K) | Viscosity (cP) | Density (g/cm ²) | Hardness (Shore) |

| HTC-215 | 1:1 | 1.5 | 1.5 million ± 400000 | 2.62 ± 0.10 | 45 ± 5 (A) |

| HTC-215-AD | 1:1 | 1.5 | 1.5 million ± 400000 | 2.62 ± 0.10 | 55 ±5(A) |

| HTC-219 | 1:1 | 1.9 | 1.6 million ± 400000 | 2.75 ± 0.10 | 40 ± 5 (A) |

| HTC-219-AD | 1:1 | 1.9 | 1.6 million ± 400000 | 2.75 ± 0.10 | 55 ±5(A) |

| HTC-220-N | 1:1 | 2.0 | 150000 ± 50000 | 2.00 ± 0.05 | 55 ± 5 (OO) |

| HTC-230 | 1:1 | 3.0 | 1.6 million ± 400000 | 2.86 ± 0.10 | 45 ± 5 (A) |

| HTC-235-T | 1:1 | 3.5 | 650000 ± 250000 | 2.95 ± 0.10 | 50 ±10(OO) |

| HTC-240 | 1:1 | 4.0 | 350000 ± 100000 | 3.20 ± 0.10 | 50 ±10(OO) |

| HTC-250 | 1:1 | 5.0 | 650000 ± 250000 | 3.30 ± 0.10 | 50 ± 10 (OO) |

/400ml双组分填缝剂.jpg)

/双组分填缝剂组合.jpg)