What is bottom filling adhesive:

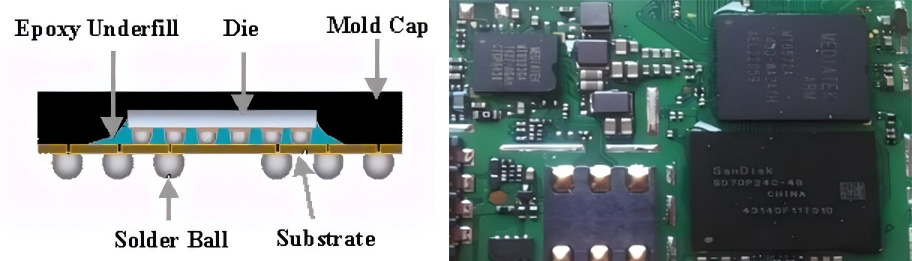

Classified by chemical category, it belongs to epoxy adhesive

Bottom filling adhesive classification:

Board level underfill:

Used for protecting BGA and CSP packaging devices in PCBA products.

Flip Chip Underfill:

Used for Flip chip protection in semiconductor device packaging.

NUF (No Flow Underfill):

Used for TCB welding process, welding and adhesive curing are carried out simultaneously.

Advantages of Low Pressure Forming Materials

Fast moldingImprove production efficiency

Why use bottom filling glue

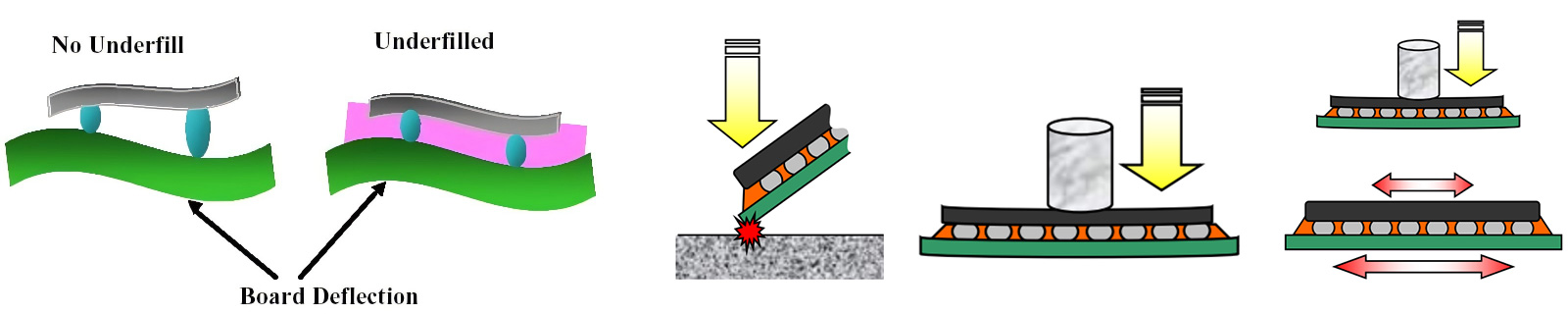

Mechanical stress: Reduce the mechanical stress generated by solder joints during product drop and bending

Thermal stress: reduce the thermal stress caused by CTE mismatch in the product

Reduce the relative deformation between the substrate and the chip in the Z-axis direction when the substrate is impacted, thereby achieving the purpose of protecting solder joints

Bottom filling application classification

BGA/CSP: Used for bottom filling of BGA and CSP devices in PCBA to improve the temperature shock and drop resistance of PCBA Require fast flow, repairability, and reliability

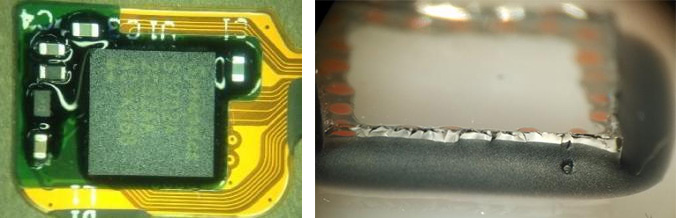

QFN: Used for QFN protection on FPC, suitable for "mouth" type dispensing

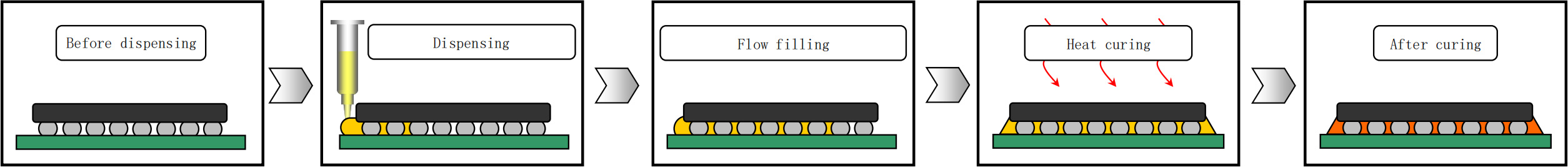

BGA Bottom Filling Glue Process

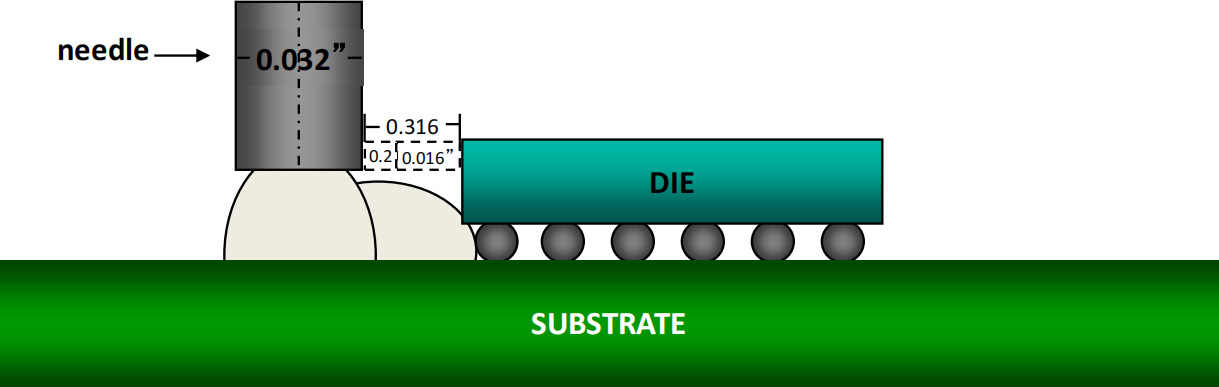

The distance between the dispensing needle and the component

Usually equal to half the outer diameter of the dispensing needle plus 0.2mm

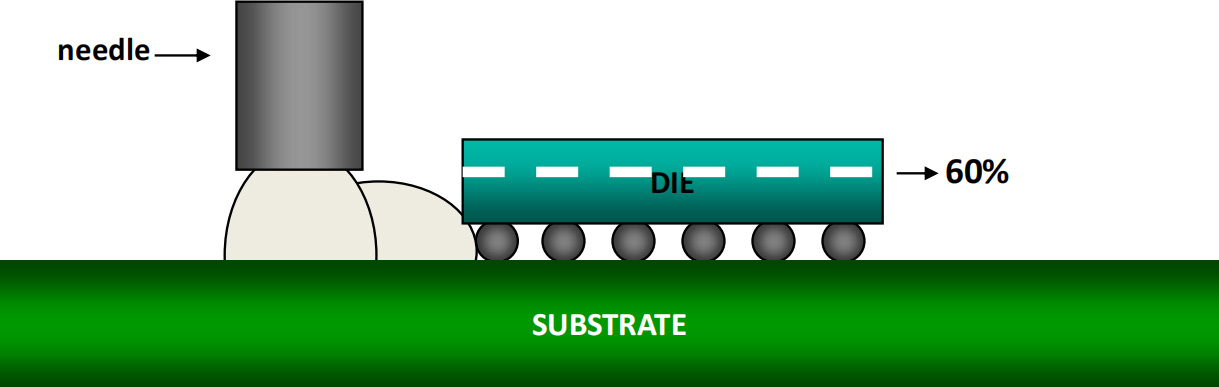

The height of the dispensing needle from the PCBA

Usually 60% to 80% of the component height, or 60% to 80% of the needle inner diameter, should not be less than 50% of the needle inner diameter

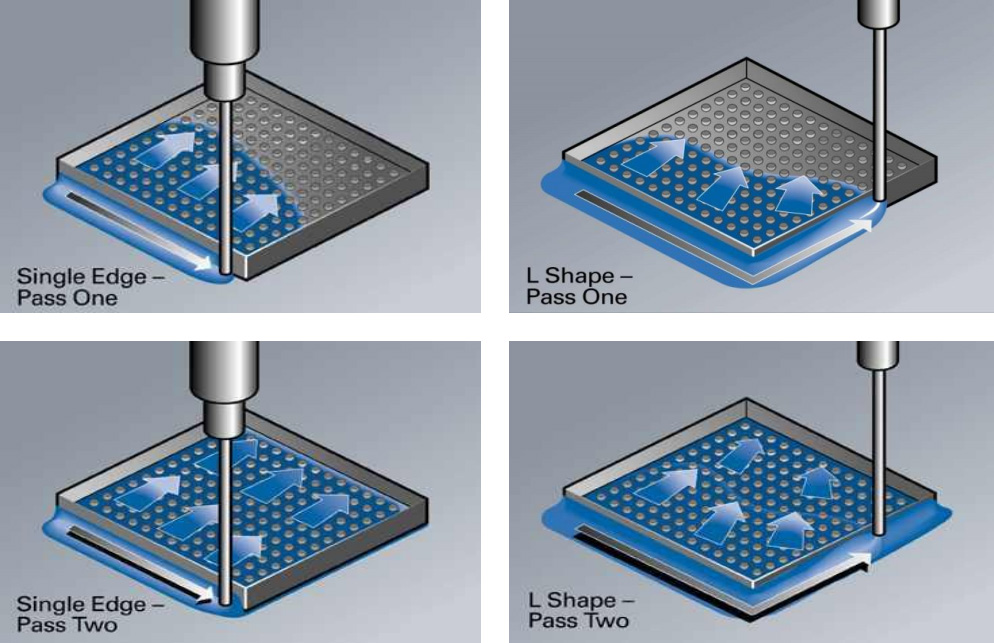

Dispensing method

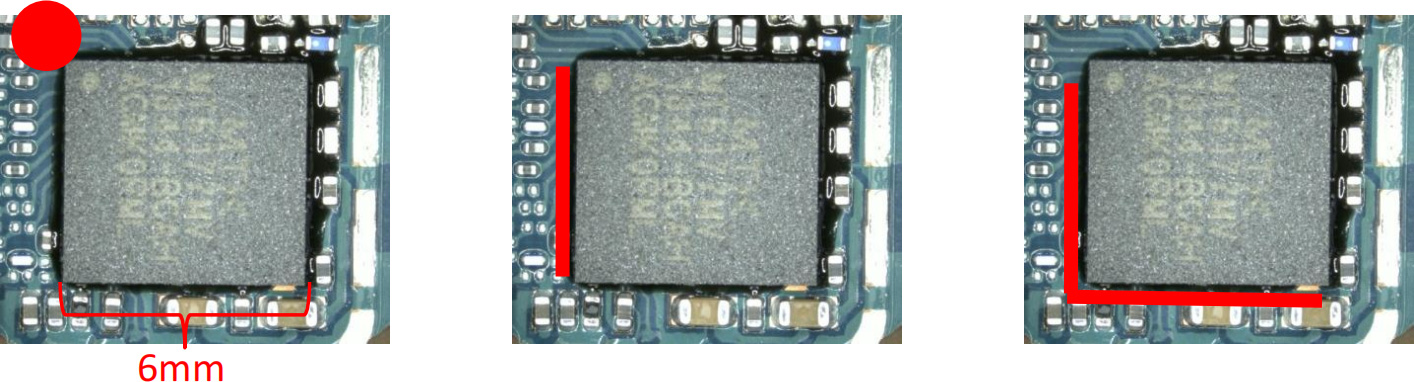

Corner Glue: Apply glue to one corner, and the glue flows to the other side; Usually used for small chips with a size of 6mm * 6mm;

Type I dispensing: dispensing along one side of the chip, suitable for small chips

L-type dispensing: suitable for medium and large-sized chips, and requires fast filling speed and large adhesive volume

Glue dispensing path and glue flow path

Glue dispensing volume

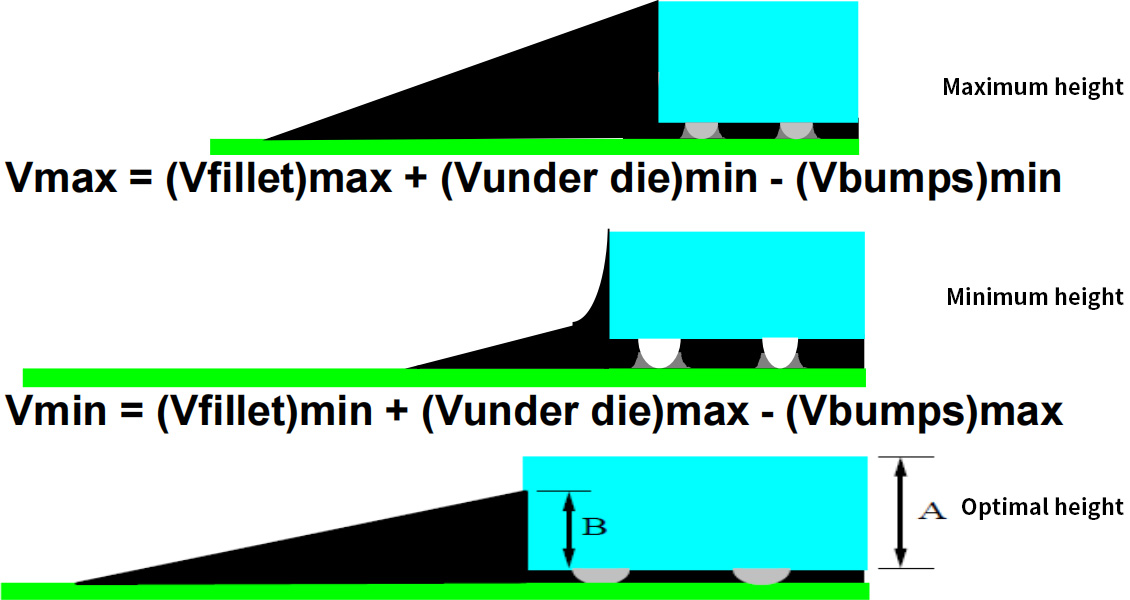

The optimal height for the overflow adhesive layer is 2/3 of the chip thickness (B=2/3A)

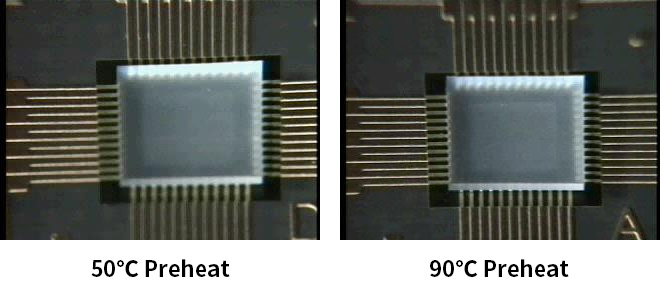

PCBA preheating

Heating significantly reduces the viscosity of the adhesive, thereby improving its flowability at the bottom of the component and increasing dispensing speed and efficiency

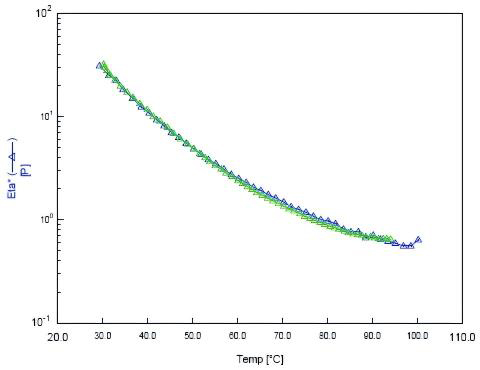

The relationship between viscosity and preheating temperature

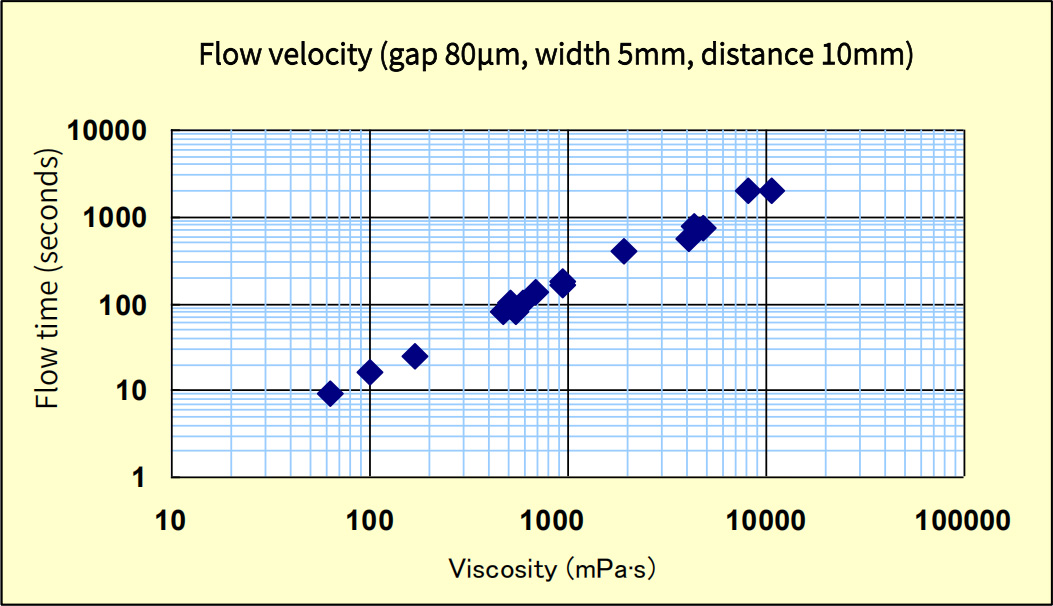

The relationship between flow velocity and viscosity

Curing method

Oven: Batch curing, commonly used by component manufacturers

Reflow soldering: an assembly line operation, commonly used for terminal machines

Heating table, vertical furnace: generally used for maintenance stations

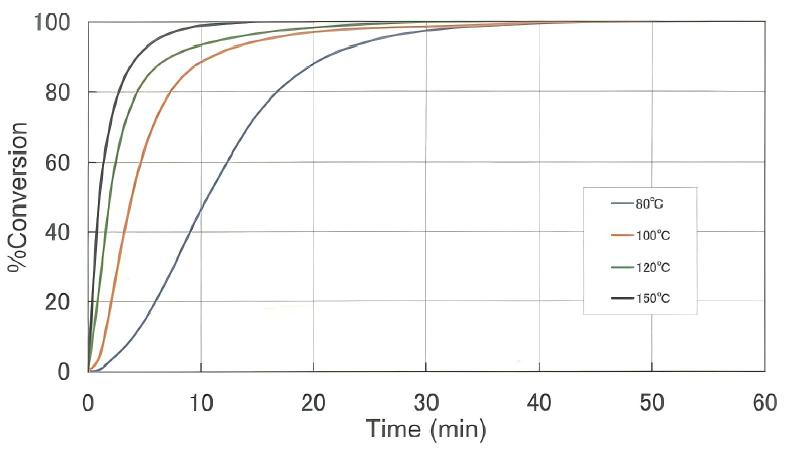

Water curing curve

Water curing curve

Repair:

heat gun

Bamboo sticks/tweezers

Test method:

1. Temperature: Shovel glue at 150 ℃, take parts at 350 ℃

2. Requirement: The distance between the gun and the board is 3-5mm