Fast molding, low temperature, low pressure, flexibility, flame retardancy, corrosion resistance

Single station cycle time during mass production: 5~60 seconds

Instant molding, no need for post-processing

Injection molding temperature: 180~250 ℃

Material softening point: 120~210 ℃

Injection pressure: 5~40 bar

Hardness: Shore A 80~Shore D 55

Fracture elongation rate: 100%~800%

Flame retardant rating certification: UL 94-V0

Resistant to medium strong acid and medium strong alkali

Advantages of Low Pressure Forming Materials

Fast molding Improve production efficiency

Low temperature, low pressure, flexibility, corrosion resistance Protection components

Low temperature, low pressure environmental protection and energy conservation

Low temperature, low pressure, flame retardant safety

Advantages of Low Pressure Forming Materials

Fast molding Improve production efficiency

Low temperature, low pressure, flexibility, corrosion resistance Protection components

Low temperature, low pressure Environmental protection and energy conservation

Low temperature, low pressure, flame retardant Safety

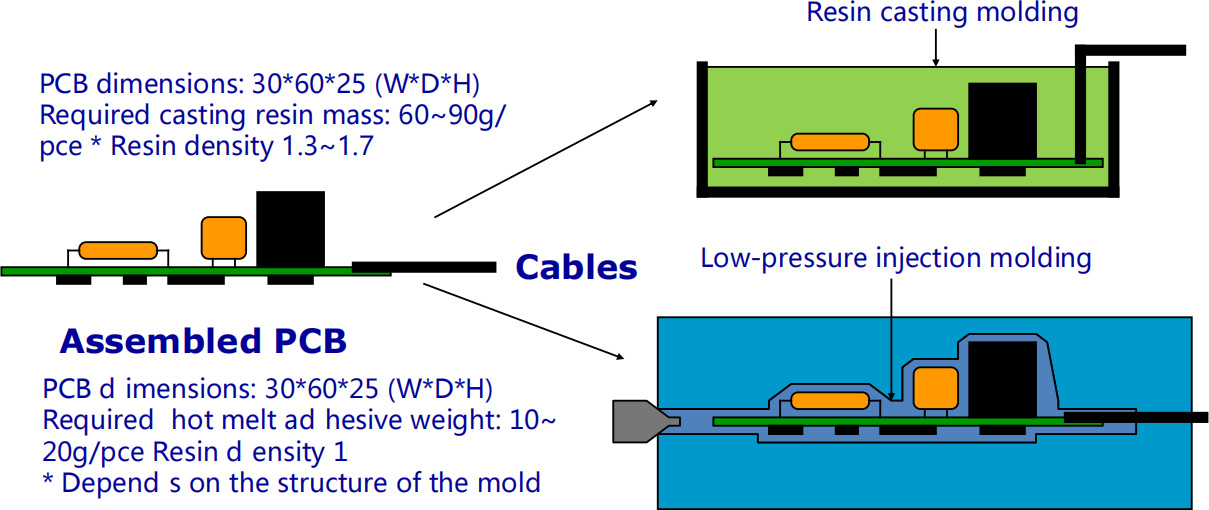

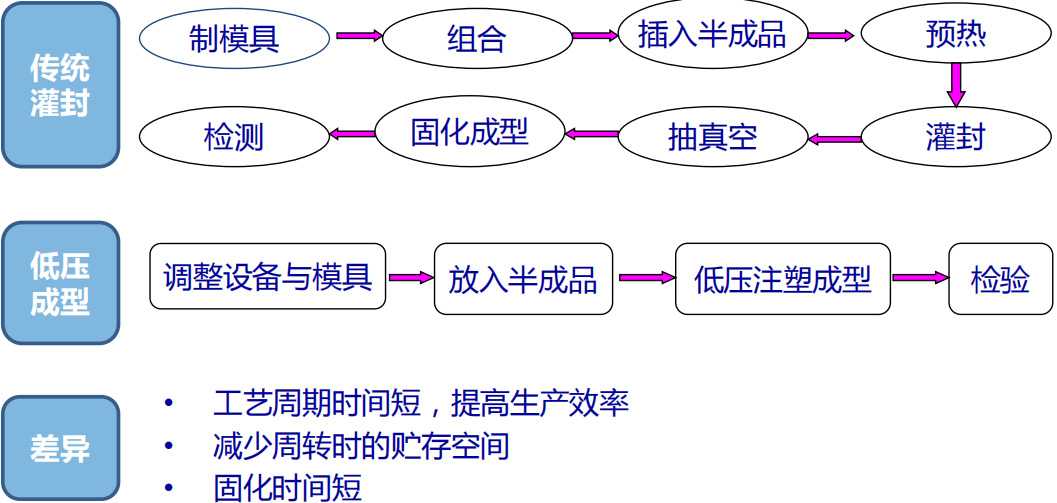

Comparison with traditional encapsulation molding

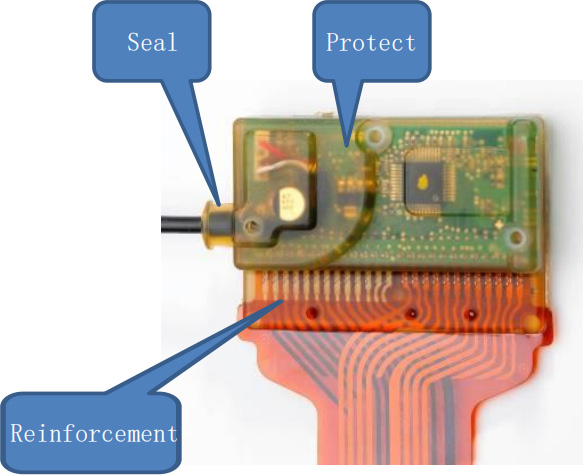

The function of low-pressure forming materials

Replace potting and traditional plastic injection molding processes

Sealing and protection of electronic components

Sealing and Protection of PCB

Protection and reinforcement of connector solder joints

Comparison with traditional high-pressure injection molding

| comparison items | Low pressure injection molding | Traditional engineering plastic injection molding |

| material | PA-HMA | ABS, PBT, PP, etc |

| Injection pressure | 5~40bar | 400~1300bar |

| injection temperature | 180~240°C | 240~300°C |

| clamping force | 1 ton | Over 50 tons |

difference

Lower injection molding temperature reduces temperature impact on components

Injection molding and clamping pressure are smaller, reducing pressure impact on components

Comparison with traditional encapsulation molding

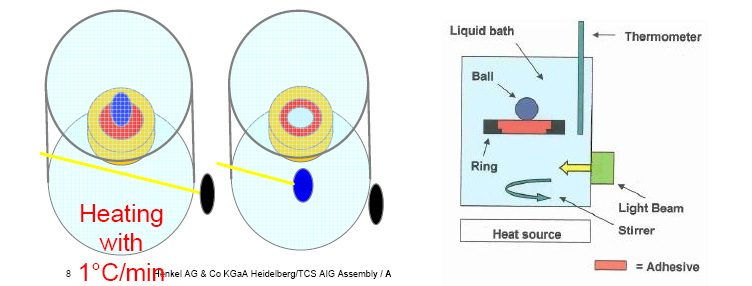

Softening Point - Global Method

The PA (red) material in the circular ring (yellow) is continuously heated up, and when the ball on the PA material falls off, it is the softening point of the material.

Product Selection

HS105 and HS106 have a high softening point and hardness, making them suitable for applications with high temperature resistance requirements

HS101, HS107, HS108, and HS109 have high adhesive strength and are suitable for wire and connector applications

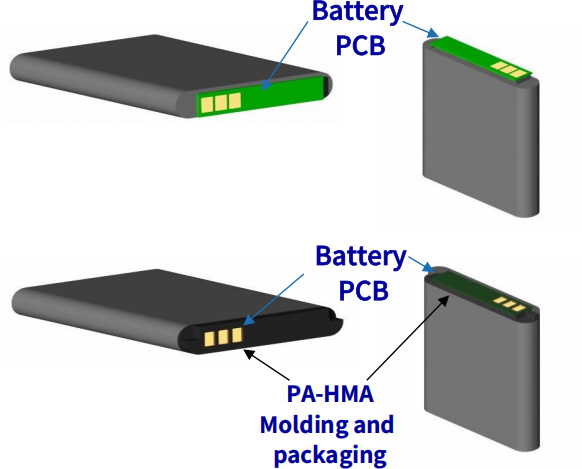

HS101, HS105, and HS102 are commonly used in mobile battery applications

HS107 has a larger temperature resistance range and better applicability, ranging from -40 to 120 ℃

The product is available in two colors: amber and black

| Application point | requirement | suitable for products |

| After packaging, it serves as the outer surface of the product | high hardness | HS105、HS106 |

| high temperature resistance | High softening point | HS105、HS106 |

| Original mobile phone battery | Fast cooling speed and high efficiency | HS101、HS105 |

| new battery | Good adhesion performance, low injection molding temperature | HS102 |

| Wire connector | High adhesive strength requirements | HS101、HS107、HS108、HS109 |

| urea tube | Low temperature resistance, high temperature resistance, UV resistance | HS107 |

mobile phone battery

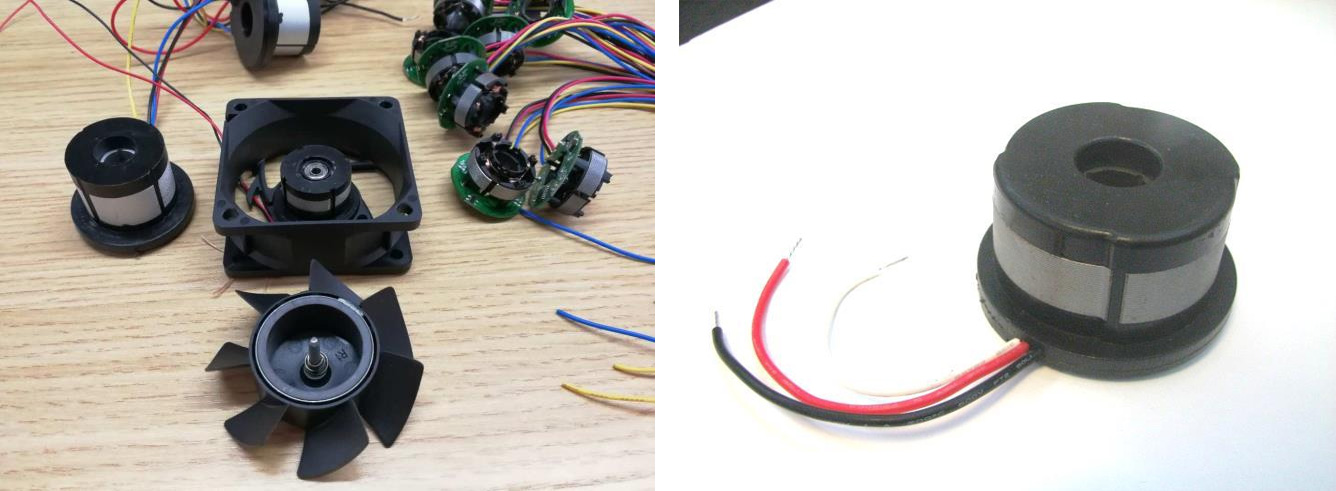

fan stator

Application point:

Fan electronic packaging

requirement:

Low temperature resistance -40 ℃, high temperature resistance 100 ℃, no cracking after 168 hours

-Cold and hot shock at 40 ℃~80 ℃ for 72 hours

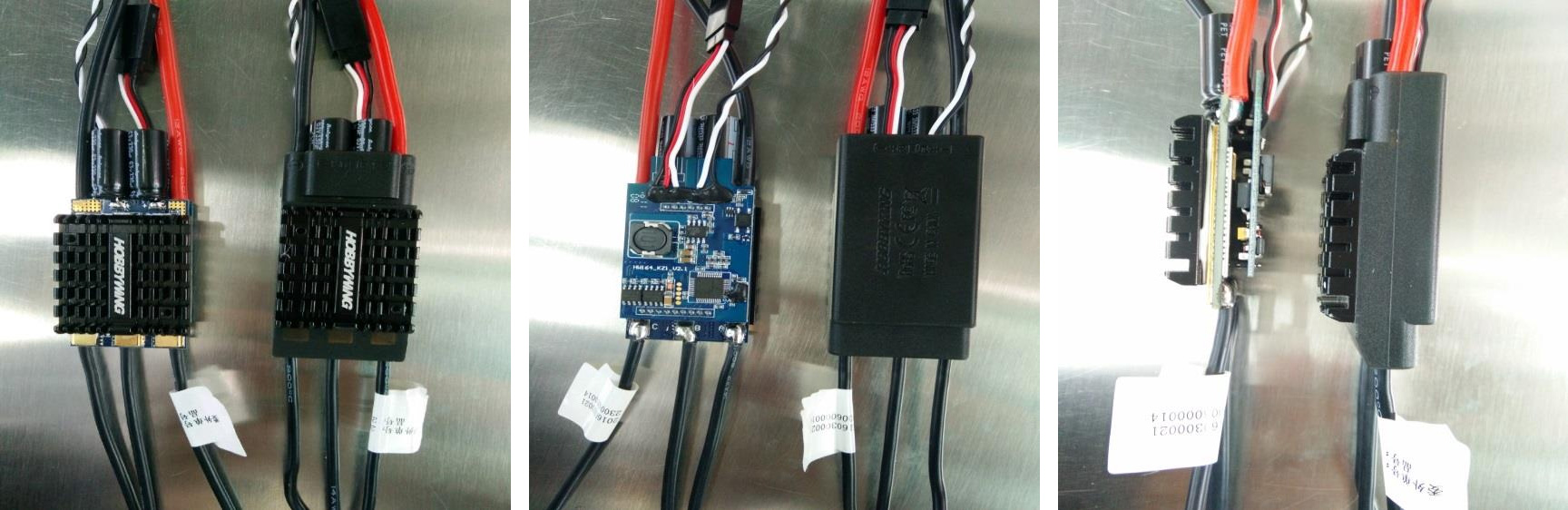

PCB package

Application point:

Unmanned electromechanical PCB packaging

requirement:

Resistant to low temperatures of -20 ℃ and high temperatures of 80 ℃ without cracking

No damage to components and wiring before and after injection molding

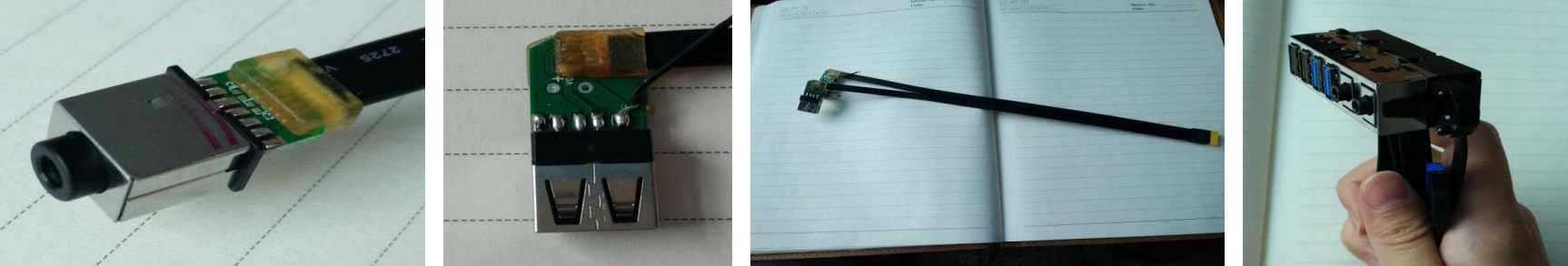

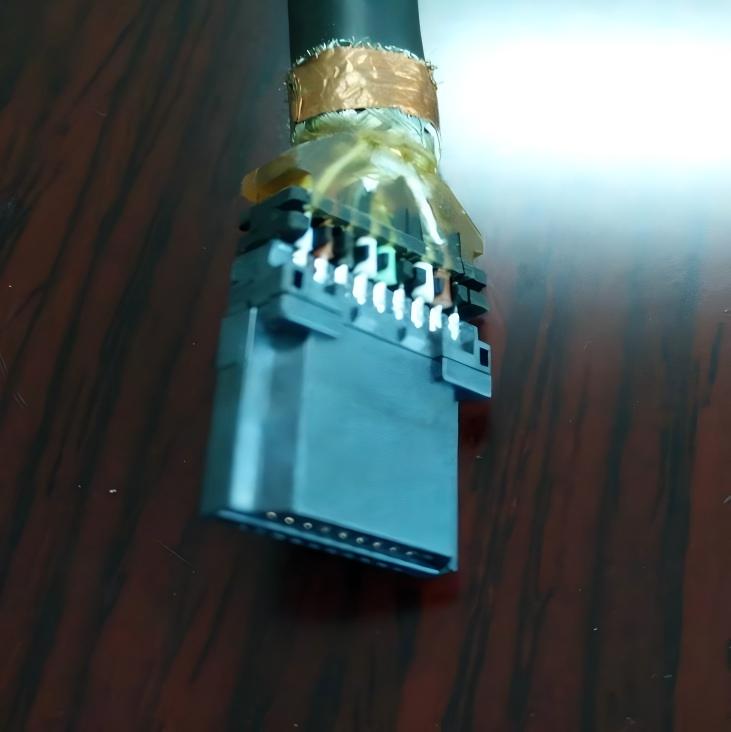

computer cable

Application point:

The connection cables between the USB interface, audio interface, etc. on a personal computer or server and the motherboard, as well as the solder joint protection between the connection cables and the USB interface, audio interface, etc.

requirement:

Protect the solder joints of the connecting wires on the interface PCB

During the injection molding process, the connecting wires and solder joints must not be damaged

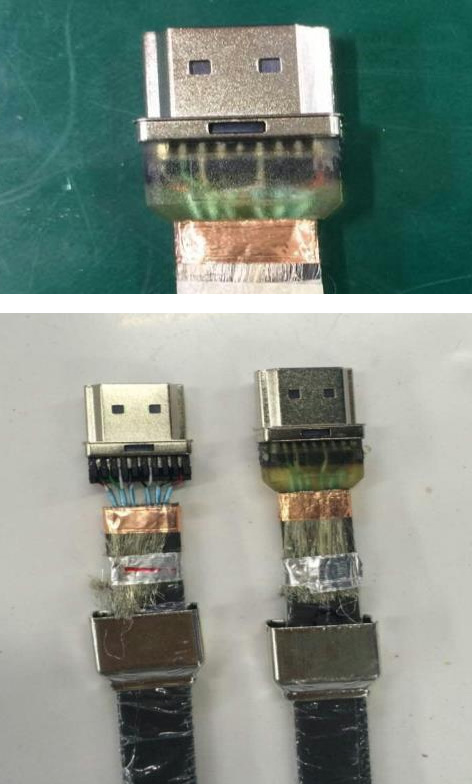

HDMI cable

Application point:

Encapsulation protection of HDMI cables and connector solder joints

requirement:

Protect solder joints from bending

The welding points and connections during the injection molding process must not be damaged

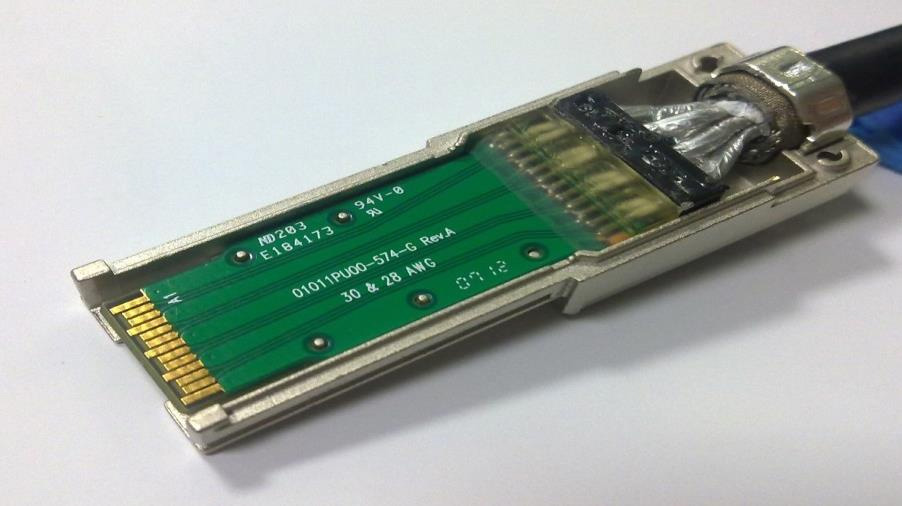

High speed transmission line

Application point:

Encapsulation protection of PCB and joint solder joints in high-speed transmission lines

requirement:

Protect solder joints from bending

The welding points and connections during the injection molding process must not be damaged

Good insulation, appropriate dielectric constant

HDMI cable

Application point:

Encapsulation protection of HDMI cables and connector solder joints

requirement:

Protect solder joints from bending

The welding points and connections during the injection molding process must not be damaged

| project | HS101 | HS102 | HS105 | HS106 | HS107 | HS108 |

| Softening point (℃) | 160~170 | 130 | 190 | 210 | 175 | 150~160 |

| Low temperature resistance performance (℃) | -40 | -40 | -25 | -15 | -40 | -40 |

| Tensile strength (MPa) | 8.0 | 3.2 | 13.93 | 12 | 9 | 6.3 |

| Elongation rate (%) | 650 | 80 | 544 | 200 | 600 | 650 |

| Viscosity (mPa · s) | 4000@200 ℃ | 2700@160 ℃ | 4500@210 ℃ | 3500@240 ℃ | 4200@210 ℃ | 3600@200 ℃ |

| Hardness (Shore D) | 40 | 32 | 45 | 50 | 42 | 37 |