High thermal conductivity, low thermal resistance;

No need for primer, strong adhesion, wide bonding range, and versatile applications;

Room temperature moisture curing thermal conductive adhesive can be cured at room temperature without mixing, making it easy to use;

Heating curing type thermal conductive adhesive has a fast curing speed and can be used for reflow soldering;

Superior resistance to high and low temperatures, weather, aging, and electrical insulation;

Superior chemical and mechanical stability;

Passed UL94V-0 flame retardant certification and RoHS hazardous standard verification.

Applied for bonding or sealing between heating and cooling surfaces, without the need for device fixation,

Fixing vertical capacitors and inductors on PCB board

Paste the temperature sensor and fill the gaps between the devices to be measured;

Fixing the wiring harness on the power board

Thermosetting thermal conductive adhesives can be used for large-area bonding,

Thermosetting thermal conductive adhesives are suitable for heating and curing applications, such as reflow soldering.

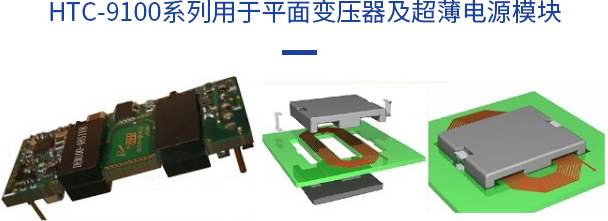

Single component heating cured liquid thermal conductive silicone adhesive, with thermal conductivity and bonding effects on electronic devices. Has good adhesion to various materials such as copper, aluminum, stainless steel, and circuit boards. solid

Without the release of by-products, it can be used in large-scale, deep, and completely enclosed situations. The series of products can be used for bonding the magnetic core and PCB in flat transformers, and can also be used for high-power fast charging power supplies

PCB bonding. Heating and curing at high temperature, the hardness after curing is 90 (ShoreA), which not only has a thermal conductivity of 4.0 w/m * K, but also has an adhesive strength of up to 5 MPa and a certain degree of elasticity. The transformer vibration magnetic core does not produce

Cracks. Welcome to call for sample testing.

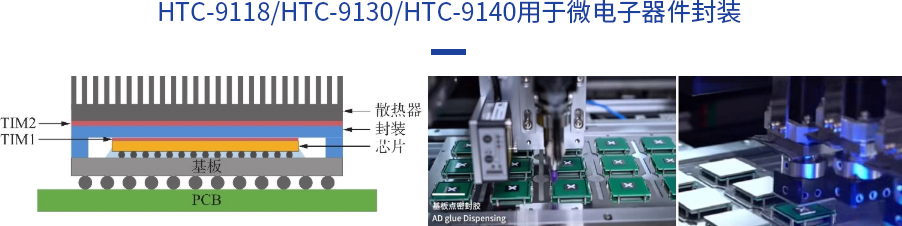

A typical schematic diagram of the heat dissipation path for microelectronic packaging devices. High power chips generally use reverse soldering technology to timely transfer heat to external heat sinks through upward heat dissipation channels. The "Chip-TIM1-Package (Heat Dissipation Cover) - TIM2-Heat Sink" is the main heat dissipation path for the chips inside the package during operation. The ideal thermal interface material for microelectronic packaging should be composed of a material that balances low adhesive layer thickness, high flexibility, high thermal conductivity, and low contact thermal resistance.

TIM1 is applied between the chip die and the chip casing to conduct harmful heat to the external area of the semiconductor package. Therefore, the compressive and shear strength as well as thermal conductivity of TIM1 material are important indicators. Due to the fact that TIM1 is the intermediate layer between the silicon chip and the metal cover plate, there is a significant difference in the thermal expansion coefficient between the silicon chip and the metal cover plate. In addition, the flip chip assembly process includes several curing process steps and temperature cycling processes. The thermal expansion coefficient and reflow resistance of TIM1 material are important performance parameters.

HTC-9118/HTC-9130/HTC-9140 is a single component heat cured liquid thermal conductive silicone adhesive with thermal conductivity and bonding properties for electronic devices. Has good adhesion to various materials such as copper, aluminum, stainless steel, and circuit boards. Curing without the release of by-products, it can be used in large areas, deep areas, and completely enclosed situations. Does not corrode metal and non-metal surfaces. Before solidification, it is a viscous liquid that can flow under a certain pressure. After curing, it closely adheres to its contact surface, forming strong adhesive properties. This series of products has the advantages of high thermal conductivity, good insulation performance, and ease of use, and can withstand secondary reflow soldering. It can be used as the thermal interface material corresponding to TIM1 in the microelectronic packaging shown in the picture. It can bond the IC top cover to the chip and conduct heat. The viscosity of HTC-9118, HTC-9130, and HTC-9140 is moderate, and a very fine dispensing head can be used to control the amount of glue. It has better bonding and thermal conductivity effects for situations where the bonding thickness is ≤ 0.5mm.

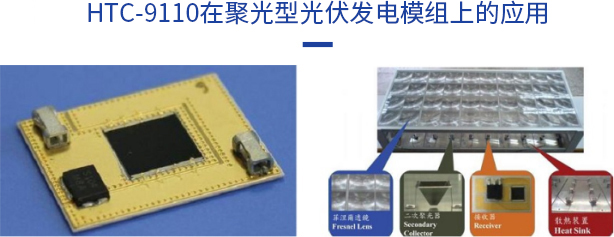

A single component heat cured thermal conductive adhesive with high thermal conductivity, with a thermal conductivity coefficient of 1.0W/m · K (ASTMD5470), and a bonding strength of over 3MPa after complete curing, which needs to be cured under heating conditions. This product has stable quality and can maintain stable adhesion and thermal conductivity for a long time at temperatures ranging from -50 ° C to 200 ° C. It can be used in HCPV high concentration photovoltaic cell modules, applied to the bottom of the photoelectric conversion module or directly applied to the back plate, bonding the photoelectric conversion module to the back, and curing can be completed after about 10 minutes of storage at 150 ° C. At the same time, because TC-9110 has good thermal conductivity, it can conduct the heat generated by solar radiation from the bottom of the module to the back plate during operation, and then dissipate it into the air or be carried away by the cooling system tightly attached to the back plate. The thermal conductivity of the series products ranges from 1.0W/m · K to 3W/m · K. Welcome to call for sample testing.

Performance indicators of single component heat cured thermal conductive adhesive

| Product Name | Thermal conductivity (W/m · K) | Viscosity (cP) | Density (g/cm ²) | Curing time (min) | Hardness (Shore A) | Shear strength (MPa) |

| HTC-9100 | — | 440 thousand | 1.60 ± 0.20 | 10@150 °℃C | 55±15 | 2.3 |

| HTC-9110 | 1.0 | 80 thousand | 2.50 ± 0.20 | 10@150 °C | 80 | 5.3 |

| HTC-9115 | 1.5 | 110000 to 50000 | 2.60±0.10 | 60@150 °C | 72.5±12.5 | 2.6 |

| HTC-9118-H | 2.0 | 70 thousand | 3.00 ± 0.20 | 10@150 °C | 94 | 6.1 |

| HTC-9120 | 1.8 | 750000 to 200000 | 2.70±0.15 | 30@150 °C | 70 to 10 | 1.1 |

| HTC-9130 | 3.0 | 80 thousand | 3.25±0.20 | 5@150°C | 93 | 4.5 |

| HTC-9140 | 4.0 | 160 thousand | 3.40±0.30 | 10@150 °C | 94 | 5.5 |