DP-F7000 is a ceramic filled silicone self-adhesive pad with high thermal conductivity. It has a gray appearance, a thickness of 0.5-8mm, a thermal conductivity of 7.2W/m · K, a working temperature of -50-200 ℃, and UL94 V0 fire resistance. It is easy to operate and adapts to rough surfaces with high deformation, providing efficient heat dissipation for high-power equipment

Core strengths

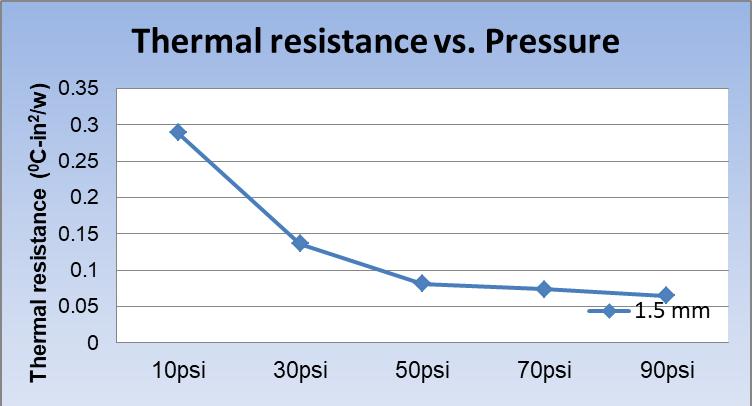

【 High thermal conductivity, low resistance, efficient heat dissipation 】 The thermal conductivity coefficient can reach up to 7.2W/m · K, with a thickness of 1.5mm and a thermal resistance of only 0.289 ℃· in ²/W under 10psi pressure. High power devices can quickly dissipate heat, increasing heat dissipation efficiency by 90% compared to conventional products

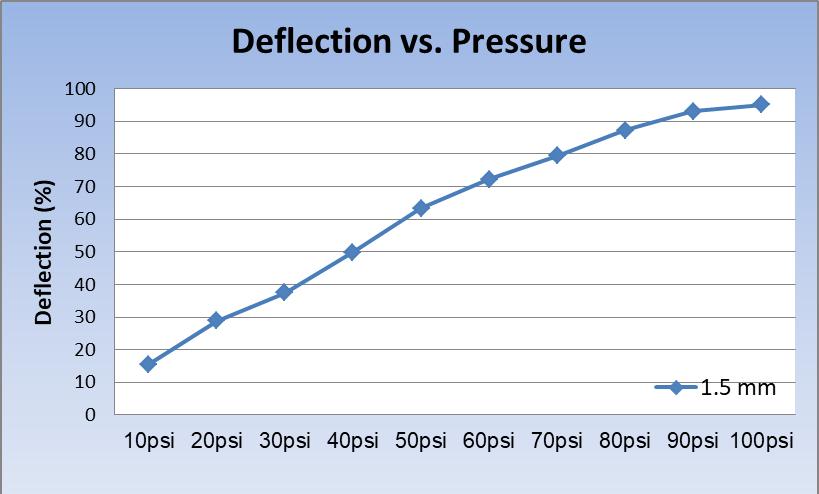

【 High deformation filling, strong adhesion 】 With 50 Shore 00 soft properties, the deformation of 1.5mm thickness and 60psi pressure can reach 73%, which can perfectly fit high roughness and complex morphology surfaces, seamlessly filling small gaps

【 Easy to self adhere, efficient assembly 】 With natural adhesive properties, there is no need for additional coating, and the film can be peeled off and applied immediately to avoid residual adhesive contamination of the device. It is compatible with automated production lines and manual installation, greatly simplifying the assembly process

【 Safe and weather resistant, stable and reliable 】 The working temperature covers -50-200 ℃ and can withstand extreme high and low temperatures; UL94 V0 level fire certification, dielectric breakdown strength>7kV/mm, excellent insulation performance, long-term use without aging failure risk

Applicable scenarios

Core application devices/components

New energy vehicles: battery pack cooling module, motor controller, 7.2W high thermal conductivity suitable for high-power cooling, wide temperature characteristics resistant to extreme on-board environments

Industrial high-power electronics: inverters, IGBT power modules, 73% high deformation filling rough surfaces, low-pressure installation without damaging precision components

High end servers: CPU/GPU core heat dissipation module, low thermal resistance for rapid cooling, ensuring stable operation of servers under high loads for a long time

Communication core equipment: high-power amplifier module, optical module, insulation and fire prevention meet equipment safety standards, self-adhesive design simplifies assembly process

Instructions for Use

1. Clean the surface and heat dissipation structure of the heating element with anhydrous ethanol, remove oil and dust, and air dry until there are no residues;

2. Confirm that the product thickness matches the installation gap, cut it to the required size as needed, and remove the protective film on the surface of the thermal pad;

3. Align the installation position with the thermal pad and lightly press it to ensure full contact between the thermal pad and the surface, ensuring no residual bubbles;

4. When using screws for locking or fastening, it is recommended to apply a pressure of 10-60psi to ensure a stable fit without the need for additional adhesive.

Precautions

Storage conditions: Sealed and stored in a cool and dry place (8-28 ℃), avoiding direct sunlight and high temperature and humidity environment. Shelf life is 12 months from the date of production

Usage taboos: Avoid contact with strong acids, bases, and organic solvents, and prohibit use in food contact scenarios and extreme vacuum environments

Thickness selection: Choose the appropriate thickness based on the installation gap, and it is recommended to reserve 15-25% compression to ensure the fitting effect

Customization Description: Supports cutting customization within the thickness range of 0.5-8.0mm, specific length and width dimensions and required thickness need to be provided

| technical indicators | specific numerical value | Test Standard |

| thermal conductivity | 7.2 W/m·K | ASTM D5470 |

| color | grey | visual inspection |

| Shore hardness | 50 Shore 00 | ASTM D2240 |

| tensile strength | 8 psi | ASTM D412 |

| Variable deformation @ 1.5mm, 60psi | 73% | ASTM D575 |

| Performance testing curve |  |

|